Modular Membrane Unit

Designed and built for Offshore and Onshore Applications

Modular Membrane Unit

Technical details

Wastewater Treatment Unit

The most compact and efficient solution for the treatment of wastewater both offshore and onshore.

Wastewater Treatment Unit

Technical details

Technical details

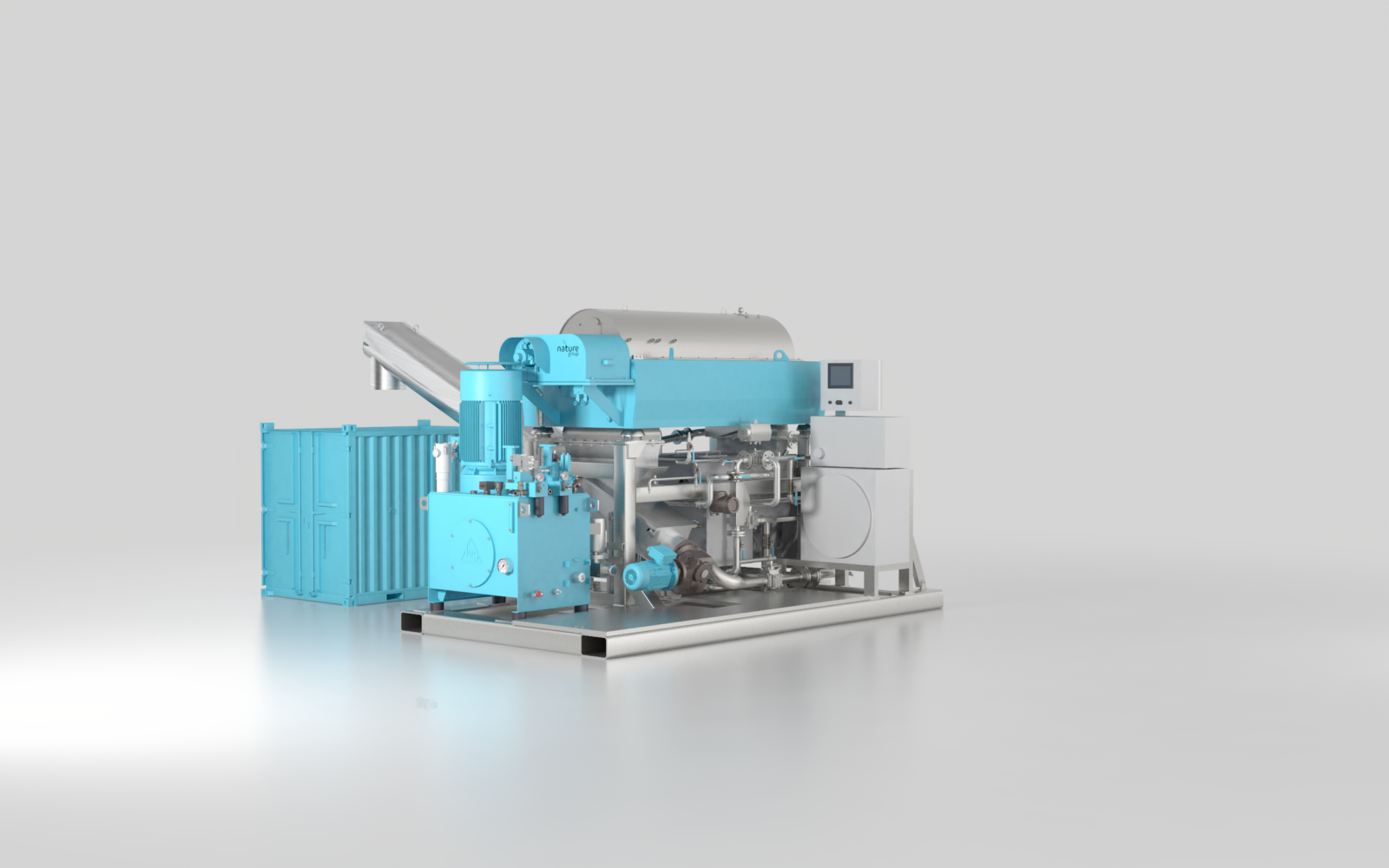

Sludge Treatment Unit

Chemically breaking the emulsion of heavy slops

Sludge Treatment Unit

Technical details

Technical details

Compact Treatment Unit

Save time and cost while minimizing the environment risk.

Compact Treatment Unit

Technical details

Technical details

Dissolved Air Flotation unit

Conterized scalable Dissolved Air Flotation unit for onshore applications.

Dissolved Air Flotation unit

Technical details

Wastewater treatment Chemicals

Onshore & offshore proven

Separation and recovery for re-use of drilling fluids

Chemicals for the treatment of Oily Sludge and OBF

Cuttings treatment unit

Eliminating the need for drilling waste to be transported to shore or re-injected.